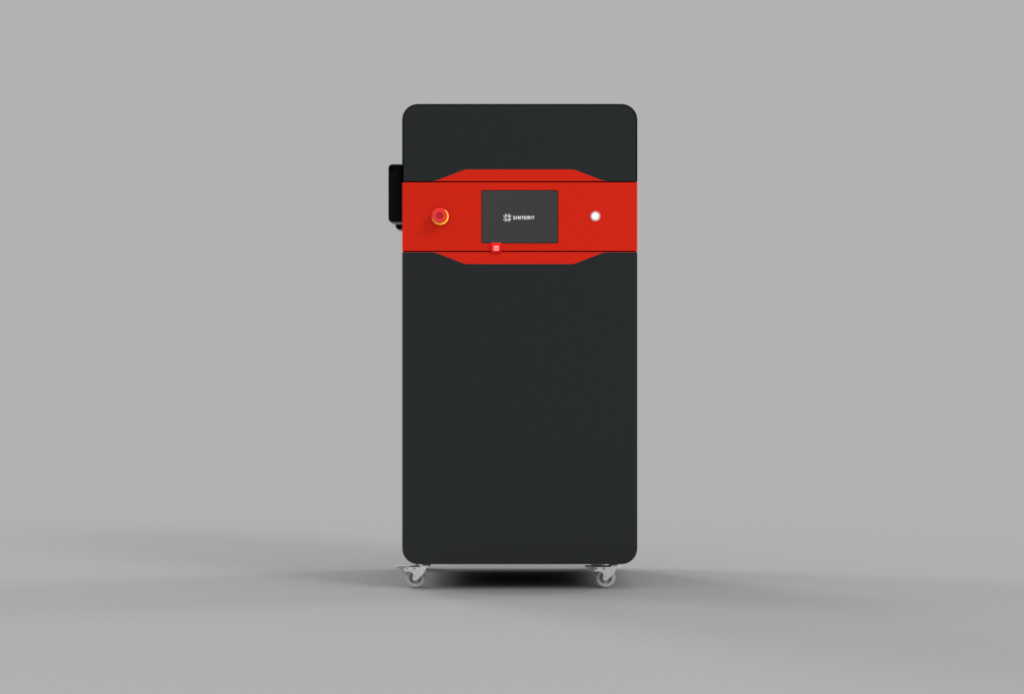

The most accessible SLS printer for professionals.

In 2014,Sinterit – technological startup was established in Krakow, whose goal is to minimize the SLS printing technology to the sizes we know from the popular FDM printers. Since then, technology reserved only for large companies has become available to almost everyone. SLS printers from Sinterit have appeared on customers’ desks. When I joined the R&D team in 2020, Sinterit faced a big challenge. The market of SLS printers began to change, competition appeared and the printer had to adapt to new realities.

Sinterit Lisa X

SLS 3D Printer

Project team:

Karol Wadycki – Product Designer

Engineering team

Photos:

Zbigniew Lewczak, Sinterit

Client:

Sinterit

Challanges

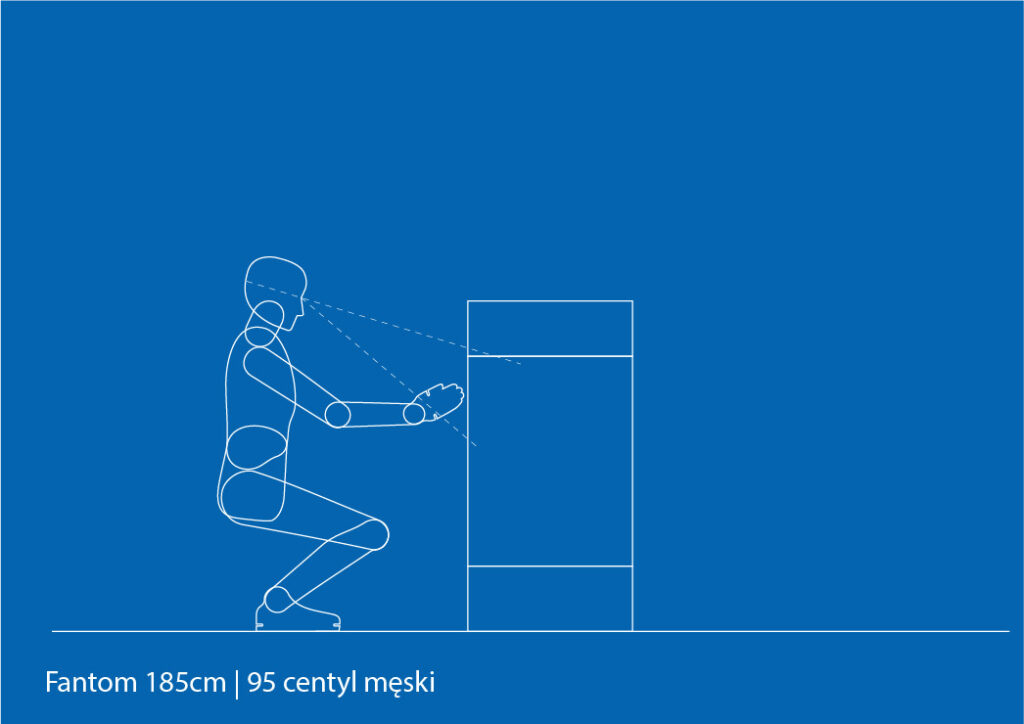

Lisa Pro – previous printer generation – has couple teething problems. Users complained about ergonomic, too many operating sides and lack of more interactive interface.

Project assumptions

- The operating space of the printer must take up as little space as possible.

- The printer should be operable from one side of the device.

- The printer must be ergonomics.

- Work with the printer should be clean – limiting contact with the powder.

Design solutions

- Large, tilt screen for better adjustment.

- One operating site – all key features are placed on the front of the printer.

- Finding and keeping style DNA for the line of Sinterit printer for better recognition on the market.

Research - look at the first generation

This was my first project at Sinterit so I wanted to better understand the product. It was necessary to made research on the Lisa Pro – the predecessor of the designed printer.

The company did not have research facilities, so in cooperation with the Product Department, I organized the space and equipment to conduct research, which later turned into a large project – UX Lab.

Personas - who prints?

The best source of knowledge about user and client were departments of Sinterit.

- Sales – information about customers and especially about their business goals

- Support – knowledge about users’ pains and problems.

- Product – defining strategic offer goals, information how we defined user inside organisation.

Dietmar, 30 – Industrial Product Designer

Goals

He is looking for a tool that will enable him to prototype faster.

Description

He has a unique blend of technical and artistic skills. He has wide range of knowledge but he is not engineer

Challanges

- He needs to rapid prototyping.

- He is not 3D printer specialist.

- He has limited time for projects, so a quick presentation of the concept is crucial for him.

John, 45 – Academic lecturer

Goals

He wants to teach his students 3D printing technology and is involved in innovative projects.

Description

He runs a 3d laboratory and is passionate about new technologies. He is really engaged in his work

Challanges

- Budget for his research

- Adjust the subject of your classes to business requirements

- Keep students interested

Cardboard, glue, wallpaper knife.

Prototyping was the most important phase at almost every design stage. After collecting all the functional requirements, the time has come for their synthesis in the form of cardboard mockups. The essence of this stage is evidenced by the fact that many developed solutions found their place in the final product.

Key design issues:

- Where the keypads should be placed to make their usage intuitive?

- How to adjust the screen to users of different heights?

- How to mark the key elements of the machine?

- How to improve the activities necessary to operate the machine?

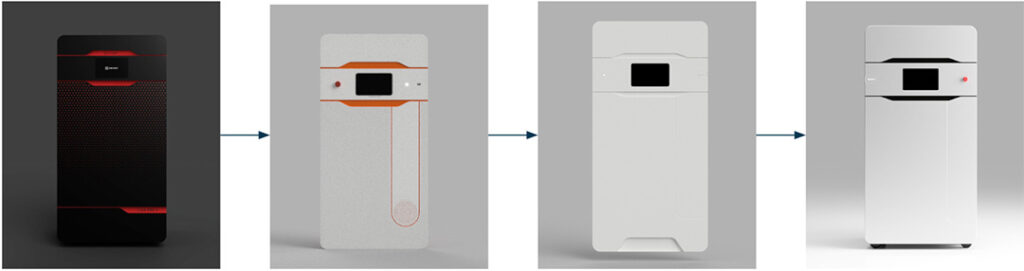

Concepts, styles, experiments

After addressed the key issues for ergonomics and the initial arrangement of functionality, the time has come for stylistic concepts. It was a time for experiments with color, form and searching for the identity of the product.

Implementation

The most difficult and crucial stage of the project was industrialization. This is the moment when the project had to face the reality of production. In this stage, I supported the constructors who started transferring the project to technical drawings and physical prototypes.

This phase is one of the biggest challenges for a designer. It requires a lot of humility, flexibility but also ingenuity to quickly find a solutions to emerging questions and problems.