The most accessible SLS printer for professionals.

In 2014,Sinterit – technological startup was established in Krakow, whose goal is to minimize the SLS printing technology to the sizes we know from the popular FDM printers. Since then, technology reserved only for large companies has become available to almost everyone. SLS printers from Sinterit have appeared on customers’ desks. When I joined the R&D team in 2020, Sinterit faced a big challenge. The market of SLS printers began to change, competition appeared and the printer had to adapt to new realities.

Project team:

Karol Wadycki – Project Manager, Product Designer, Design Leader

Agnieszka Surma – Product designer

Szymon Zamęta – Engineer

Photos:

Zbigniew Lewczak, Sinterit

Client:

Sinterit

Challanges

Multi PHS is the successor to the first post-processing station in Sinterit’s portfolio. Tests of the first generation revealed deficiencies in user interface intuitiveness and insufficient usability. The project was based on the construction of the first generation.

Long story short

Project assumptions

- Increase user protection against powder.

- Adapt the device to work with various types of powders.

- Improve the intuitiveness of working with the device – modify the user flow.

- Enhance the user experience.

- Resolve first-generation quality issues.

- Adjust the device to work with all printers in the company’s portfolio.

Design solutions

- Protective cover – transparent polycarbonate cover, protecting against powder airborne dispersion.

- Press and work – simplifying the device operation – start the process with a single press.

- Utilization of capacitive sensors for improving device operation.

- Modification of some materials.

- Development and implementation of 5 dedicated work programs.

My role

Project management

As a Project Manager in the implementation project of a new powder post-processing device, I coordinated the team, developed action schedules, and ensured effective communication, contributing to the project’s success by improving production efficiency and product quality.

Business requirements gathering

In the project, I gathered business requirements pertaining to the project, which resulted in the creation of a project charter. This involved liaising with stakeholders to define and document essential project specifications.

Usability test and users needs

I gathered user needs and experiences through usability tests and sales data analysis. This enabled us to better understand user requirements and preferences, facilitating informed decision-making throughout the project.

Designing solutions

I designed and implemented functional solutions as part of the solution design phase. This involved creating detailed plans and executing them to address project requirements effectively.

Implementation & production

I oversaw the project’s implementation into production, ensuring the accurate transfer of documentation to procurement departments and subsequently to the production department. I also provided ongoing coordination to address any emerging technical issues promptly.

Research

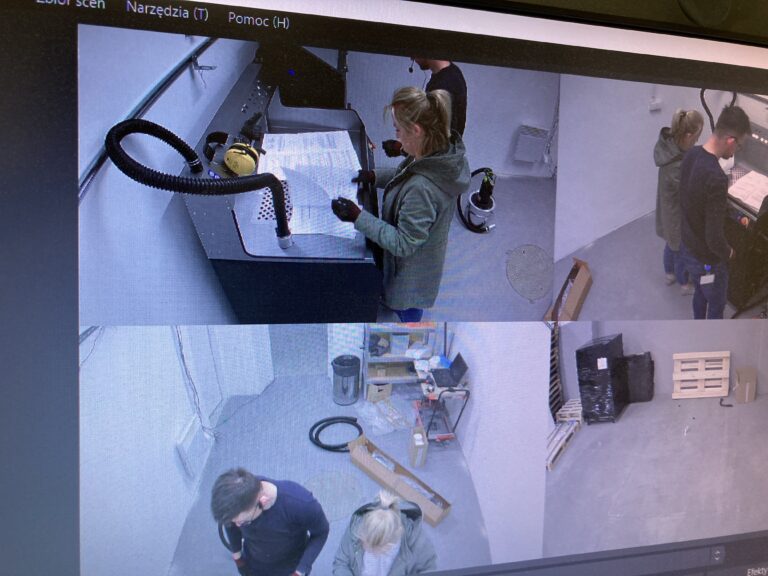

The project initiation was preceded by functional usability tests conducted on the previous generation of the device. These tests followed a predetermined scenario, with respondents selected based on specific user groups. These user groups were developed during workshops attended by members from various departments within the company.

Respondents struggled with completing tasks, which included:

- Cleaning the print from the powder.

- Refreshing the powder.

- Cleaning the device and printer.

Student at the univeristy

After training, a student should be able to operate both the printer and PHS (powder handling station) smoothly, resulting in high satisfaction with the process. In case of an issue like Wi-Fi connection failure, their first steps might lead them to YouTube, but they may not find detailed information there. YouTube typically provides general information about the process rather than specific troubleshooting guidance.

Small business owners

After reading the instructions, a small business owner should grasp the basics of the products. However, due to certain inconsistencies and lack of coherence in the instructions for the entire solution, carrying out the process may be challenging. The depowdering process should still proceed smoothly. In case of a feeder malfunction, the user will be notified of the error and which component has failed. However, the support team may currently lack sufficient experience to fully address the issue (as of the beginning of PHS shipments).

Operator at a factory

After receiving training from the employer, factory operators should be able to carry out the depowdering process smoothly. However, in the absence of knowledge about a particular process, instructions may provide conflicting information on how to execute the process (e.g., refresh).

Tests documentation

During task execution, I conducted observation of the respondents. The study was recorded, facilitating later in-depth analysis. Respondents were asked to verbally comment on the tasks they were performing.

Research insights

Respondents encountered difficulties in completing tasks.

The vertical axis represents the stages of the process that users must go through, while the horizontal axis shows the point in time when users perform each stage. The black line represents the designed flow of the process, while the colored lines represent the flow observed in respondents.

The greater the difference between the planned flow and the actual flow, the more confused users were during the process.

User satisfaction flow.

This user flow chart presents user satisfaction at various stages of the process. A significant drop in satisfaction is evident during the use of the old-generation PHS.

Fundamental insights:

- People found it hard to figure out how to use the vacuum without being taught first. They got lost during the process, which often led to not finishing the task.

- Knowing how the products work and having experience using them made it easier to finish the task correctly.

- The part where you turn on the vacuum before removing the powder wasn’t considered in the plan.

- Following the steps exactly was crucial. Even small changes made it hard to finish the task right.

- People often didn’t understand how to refresh the powder properly because it wasn’t explained well.

- Users expected the devices to stop them from making mistakes.

Bussiness goals

One of the most important inputs to the project is the business requirements. All requirements were derived from market research and meetings with Product Managers and the management team.

Bussiness and technical requirements

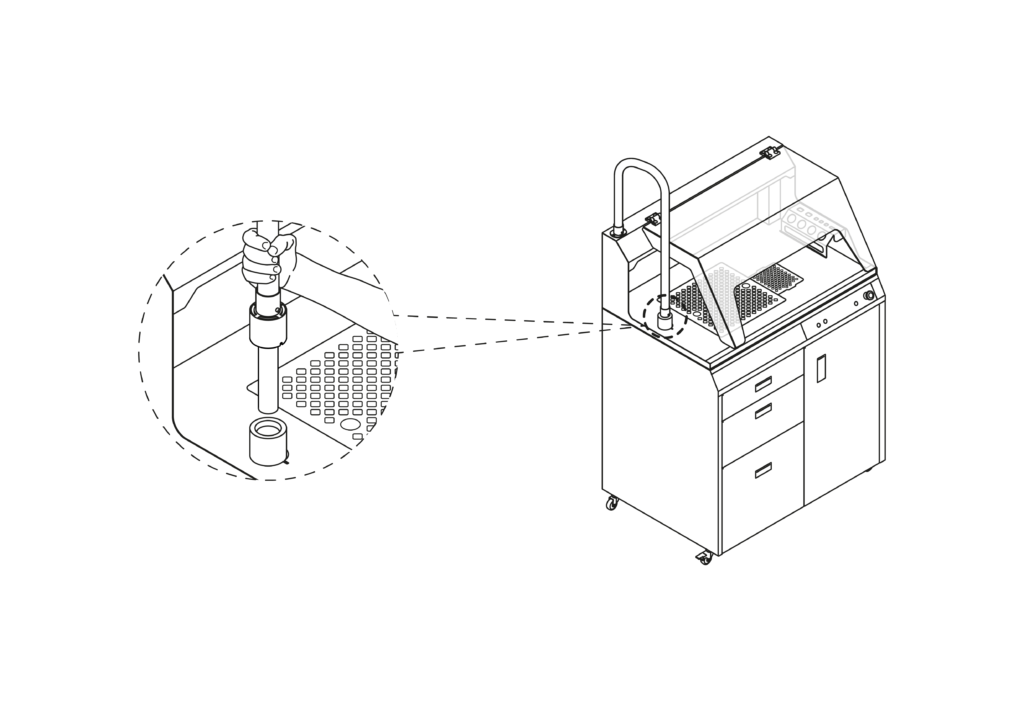

- The rigid and short suction hose makes it difficult to operate while using the cooling box.

- The air inlet to the PHS is blocked by the printout cutter.

- A large amount of powder makes it impossible to conduct the refresh process all at once. The PHS operation method complicates handling a larger amount of powder.

- The maximum amount of powder to be extracted by the PHS is 65 liters, necessitating 4 depowdering processes in the vacuum cleaner. The PHS operation method complicates handling a larger amount of powder.

- The PHS tube is too short and too rigid to perform the required tasks.

- Address quality issues (powder in the vacuum cleaner, wheels, locks, couplings).

- Resolve issues with solution delivery to the customer.

- Address communication and documentation.

- Antidust cover: The fact that the PHS is completely open poses a significant sales limitation. Customers are concerned that during depowdering the cake, there is no cover between their face and the cake.a

System architecture

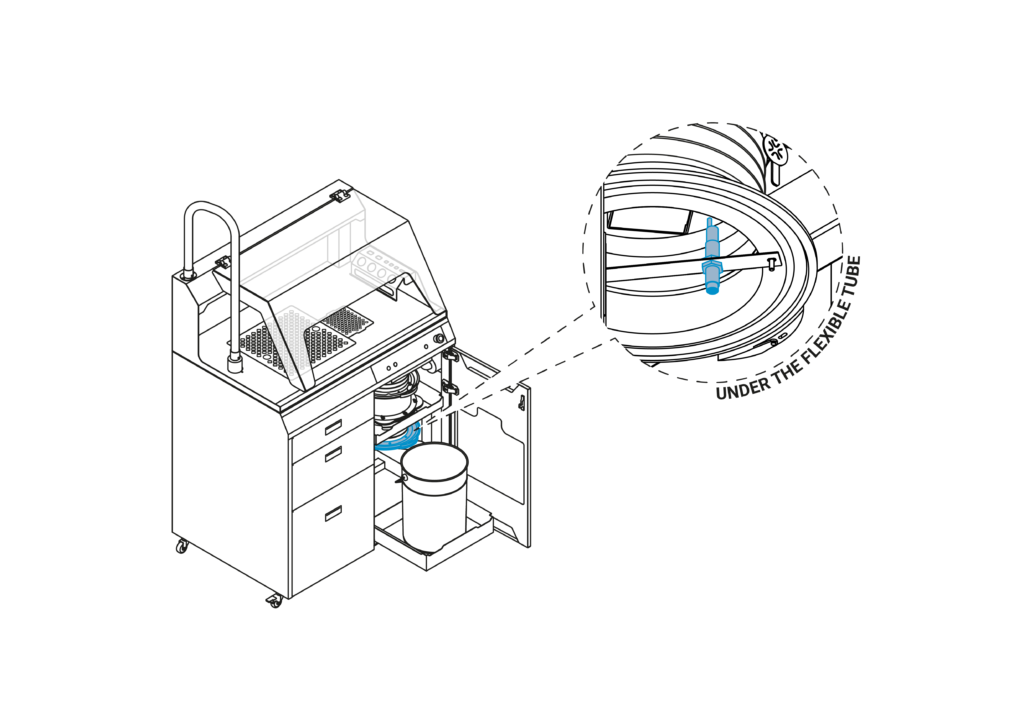

The basis for creating the control system architecture was simplifying the process to the maximum extent possible, even if it meant prolonging it. An essential aspect was minimizing the potential for errors. To achieve this, sensors were used to measure the device’s state.

Architecture of information based on simply functional divided.

- Program selector

- Depowdering

- Sandblasting

Architecture chart

The basis for creating the control system architecture was simplifying the process to the maximum extent possible, even if it meant prolonging it. An essential aspect was minimizing the potential for errors. To achieve this, sensors were used to measure the device’s state.

User flow and block diagram

Based on the gathered knowledge, I designed a user flow for the user, based on which I created a flowchart. This flowchart made communication with the programmer easier and served as a form of documentation.

The main goal was to simplify work, increase the device’s intuitiveness and minimize the path from turning on the device to starting work.

Design solution

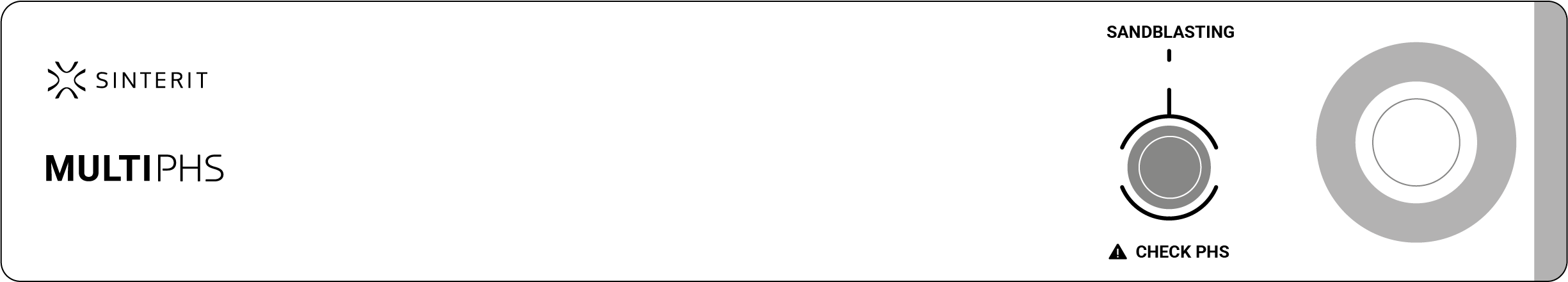

Many functions – three buttons

The control panel could have a limited number of buttons, so each button had two functions – a single press and a long press. The effect of a single press was described on the upper part of the panel, while the effect of a long press was described on the lower part.

⚠️It was a challange!

I couldn’t change the layout of the buttons or LEDs due to the stock of PCB boards. I had to manage with it in the new version of the device.

Workflow simplification – press and play

Thanks to the modification of assumptions, we managed to simplify the workflow so that the process became intuitive and error-free. Additionally, the use of sensors has enabled some tasks to be performed automatically, allowing users to start work more quickly.

👎PHS (old version, 7 steps to start)

🚀Multi PHS user flow (new version, 2 steps to start)

Mode selector

The mode selector is used to choose the appropriate program tailored to the type of material being used. Implementing a greater number of functions and programs required the introduction of a new version of the processor. The user can select one of the five predefined work programs. Some programs offer the possibility to adjust work parameters to maintain maximum flexibility for advanced users.

Sandblasting program

Sandblasting is an additional functionality. The program allows for a clean way to sandblast the print, thereby removing powder residues and ensuring a proper surface.

Summary

In this comprehensive case study, I led a project focused on enhancing device usability and functionality for diverse user groups, including university students, small business owners, and factory operators. By organizing internal workshops and conducting thorough research, I devised customized testing scenarios tailored to each user segment, pinpointing key pain points and areas for improvement in their user journey. Through meticulous user testing and observation, I gained valuable insights into user challenges and satisfaction levels, guiding the redesign process to elevate overall user experience. Drawing on these insights, I revamped the control system architecture, integrating intuitive user interfaces and advanced sensor technology to streamline processes and reduce errors. The introduction of innovative features like a mode selector, anti-dust cover, and magnetic tools holder led to significant enhancements in device usability and user satisfaction across all user segments, representing a notable advancement in device functionality and user experience.

Thank you!🎉

Thank you for your time, if you have any further questions regarding my work, please feel free to contact me!